A300+ Machine Tutorial Video

A300+ Industrial Pneumatic Spot Welder, Built-in Compressed Air Pump

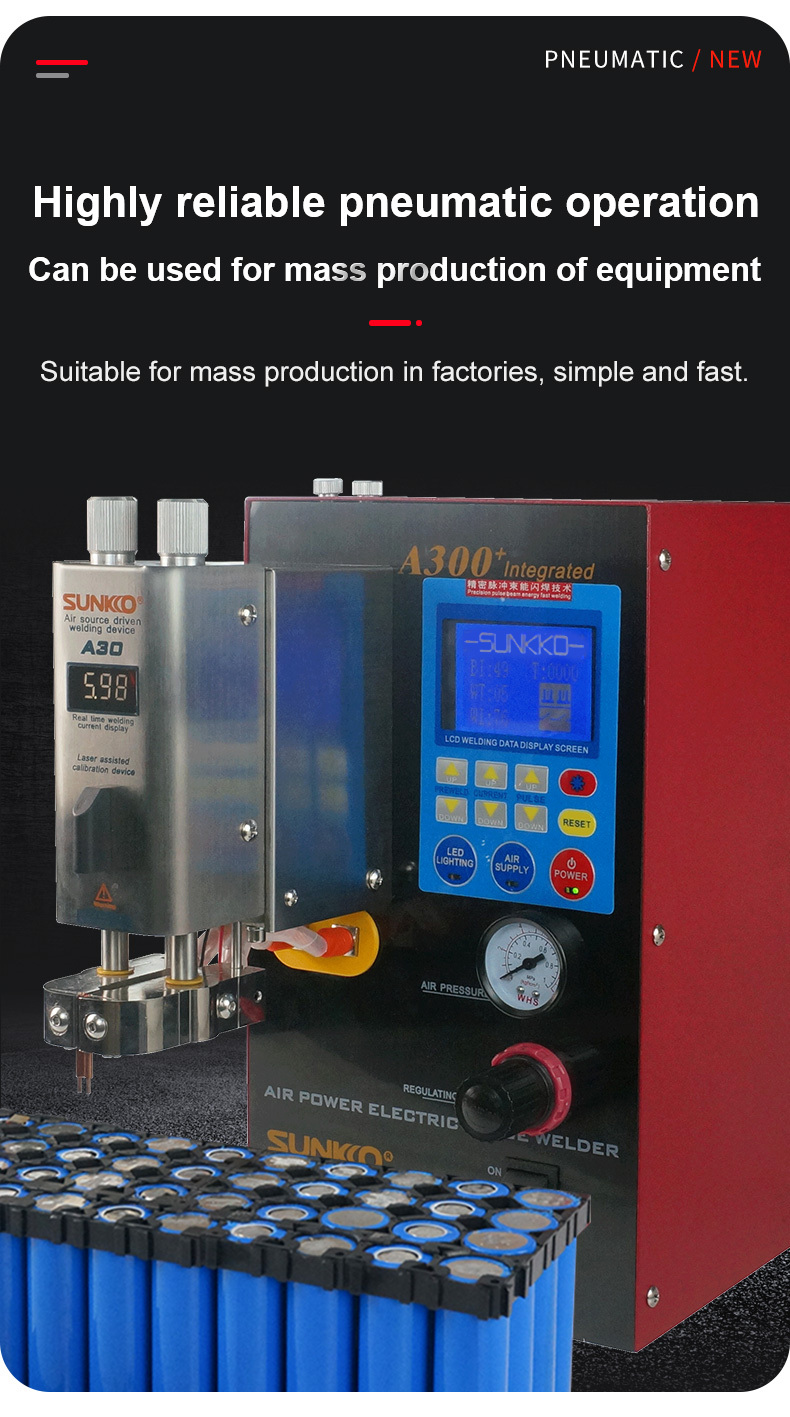

Highly reliable pneumatic operation, can be used for mass production of equipment.

Overview

High performance microcomputer high-frequency inverter spot welding machine has the world's advanced technology level, and is specially designed based on the extensive application and assembly of lithium batteries (nickel cadmium, nickel hydrogen, lithium batteries) in the world. The welding machine is controlled by a microcomputer single chip and displayed on a large blue LCD screen. It is the latest spot welding machine specially designed for high-end spot welding by our company, with the crystallization of our company's technology for a long time. The welding quality is firm, beautiful, and the performance is more stable and reliable.

It mainly has the following characteristics:

1. Microcomputer control, large LCD display, graphical display of the current working status.

2. Microcomputer single-chip control, it can realize single-pulse, double-pulse and multi-pulse welding.

3. Accurate microcomputer control: the microcomputer inside scans the input voltage at high speed for a long time, and when the current fluctuates, the compensation data will be calculated immediately, and the welding energy will be changed, no false welding or fire explosion will occur due to voltage fluctuation, and the welding effect is consistent each time. The welding spark is small, which has little impact on the battery.

4. The first detachable standardized pneumatic spot welding head, which is convenient for transportation and installation.

5. Standard pneumatic spot welding head can be assembled on gantry or automation equipment as a separate product.

6. The pneumatic spot welding head adopts a buffer design, the pressure of the two welding needles is independently adjustable, and the adjustment is convenient. When the left and right electrodes are not at the same height or there is a slight height difference between the left and right sides of the battery, the force of the two electrodes is still balanced, and the welding quality will not be affected.

7. It is equipped with laser alignment and positioning, as well as welding needle lighting device, to improve the accuracy of welding and production efficiency.

8. The pressing and reset speed of the pneumatic spot welding head are independently adjustable, and the adjustment is convenient.

9. The circuit of the pneumatic spot welding head adopts gold-plated contacts, and with digital display screen to display the spot welding voltage and current, which is convenient for observation.

10. With two-stage beam energy flash welding parameter adjustment function, pre-welding removes the oxide layer, eliminates debris, and reduces sparks; continuous welding ensures that the solder joints are beautiful and firm, and the solder joints are uniform and not black.

11. The air pressure gauge and air pressure adjustment knob are on the front of the machine, which is ergonomically designed for observation and adjustment

12. Equipped with an intelligent cooling system to adapt to long-term uninterrupted spot welding operations.

13. With automatic counting function, single-day output can be automatically counted from 0000-9999, which is convenient to calculate single-day output and improve work efficiency.

Note: Set the appropriate current level and number of pulses according to metal materials of different thicknesses

BI: (01-99 energy level) pre-welding current gear value.

WT: (01-05 pulse) number of spot welding pulses.

WI: (01-99 energy level) continuous welding current gear value.

Widely used in electric vehicles, model aircraft, rocking cars, new energy vehicles, sweeping robots, power tool laboratory teaching and other fields.

Parameter:

Model:A300+

Power Supply:AC110V or 220V

Power frequency:50Hz/60Hz

Peak output power:6KW

Peak output voltage:6V

Output current:1200A(Max)

Load duration rate:<55%

Working pressure:0.35~0.55Mpa

The max pressure:1.5kg(Single)

Arm length:146mm

The max downstroke:24mm

Air source input power:200W

The max pressure of air source:0.6Mps

Air source noise:35~40dB

A30 Pneumatic Spot Welding Head Welding Thickness:

Pure nickel welding to 18650 battery:0.1~0.2mm

Nickel-plated welding to 18650 battery:0.1~0.25mm