737G+ Machine Tutorial Video

737G+Dual Digital Display Intelligent Precision Pulse Spot Welding Machine

Features:

1.lt adopts microcomputer switch control technology.

2.It adopts precise current step adjustment controlled by microchips to achieve microcomputer precision spot welding.

3.Wider current adjustment range, single/double pulse welding mode selection, more powerful and more reliable.

4.Press the key to set welding parameters. lt is equipped with current parameters and pulse display for more precise spot welding.

5.The welding pressure of the welding needle can be adjusted based on the thickness of the weld part to get reliable welding points and more precise spot welding..

6.It is suitable for welding and assembling various mobile phone batteries and notebook batteries.

7.It is suitable for precision machining,welding,and assembly of hardware components.

Application

18650

Single row 18850 battery

Button batteries

Pouch cell

Nickel chip circuit board

Portable charger

Welding parameters

Power supply :AC220V±20V

Output power:4.3KW(Max.)

Welding current:120~1200A

Double pulses time:1-10ms

4 Pulses time:2~20m

8 Pulses time: 8~80ms

Welding thickness:0.15~0.35mm(fixed head)

0.05~0.2mm(welding pen)

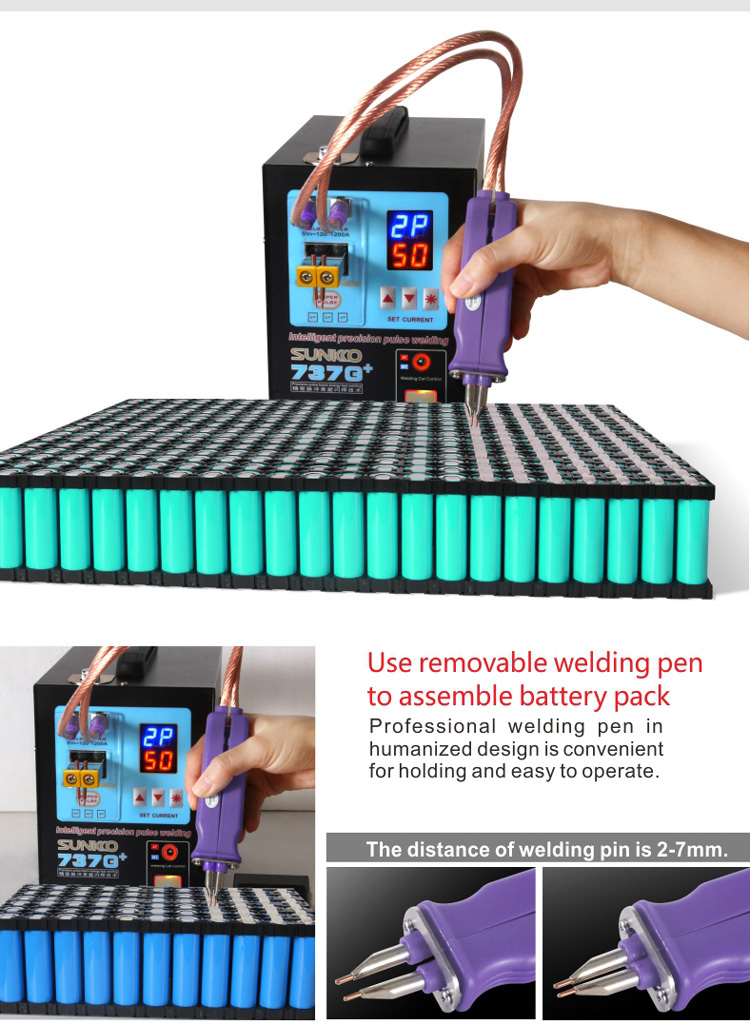

Mobile spot welding pen parameters

Welding needle spacing: 2-7mm

Total length of spot welding pen:≈580mm

Welding pen cable area: 16mm2

Size of welding pin:∅1.5mmX7mm

Packing list:

1)737G welding machine *1 set;

2)6-section fixture *1 pc

3)Hex wrench *1 pc

4)Fuse tube *2 pcs

5)Pedal switch *1 pc

6)Welding pins for fixed head *4 pcs

7)Nickel plated sample *100 pcs

8) Operation Manual*1 pc

Notices for using SUNKKO spot welding machine

1.In order to obtain good weld effect, please don't use the active socket,and should be used the wall socket to ensure stable power supply.

2.Because of the instant welding large current, rated current of tripping device of the leakage protection switch should be up to 40-63A.Lower than 40A will cause tripping.

3.Please set the pressure adjuster to the right parameter to avoid welding effect in not good.

4.Please keep the surface of welding pins clean and wipe off oxide withsand paper.

5.Please keep the welding pin in sharp shape.

6.Please do not worry about the lighting in flash. Spot welder is a highpower machine and discharging highcurrent instantaneously.Because this moment is in 20ms and it is normal.